-

fisherba wrote a new post 6 years, 4 months ago

This post was written by @ehost11 and @crpelissero as part of their senior capstone project at University of St. Thomas in St. Paul, Minnesota. The capstone course was co-taught by @tahicksonstthomas-edu and @fis […]

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of WikiWatershed, an initiative of Stroud Water Research Center designed to help people advance knowledge and stewardship of fresh water.

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of WikiWatershed, an initiative of Stroud Water Research Center designed to help people advance knowledge and stewardship of fresh water. New to EnviroDIY? Start here

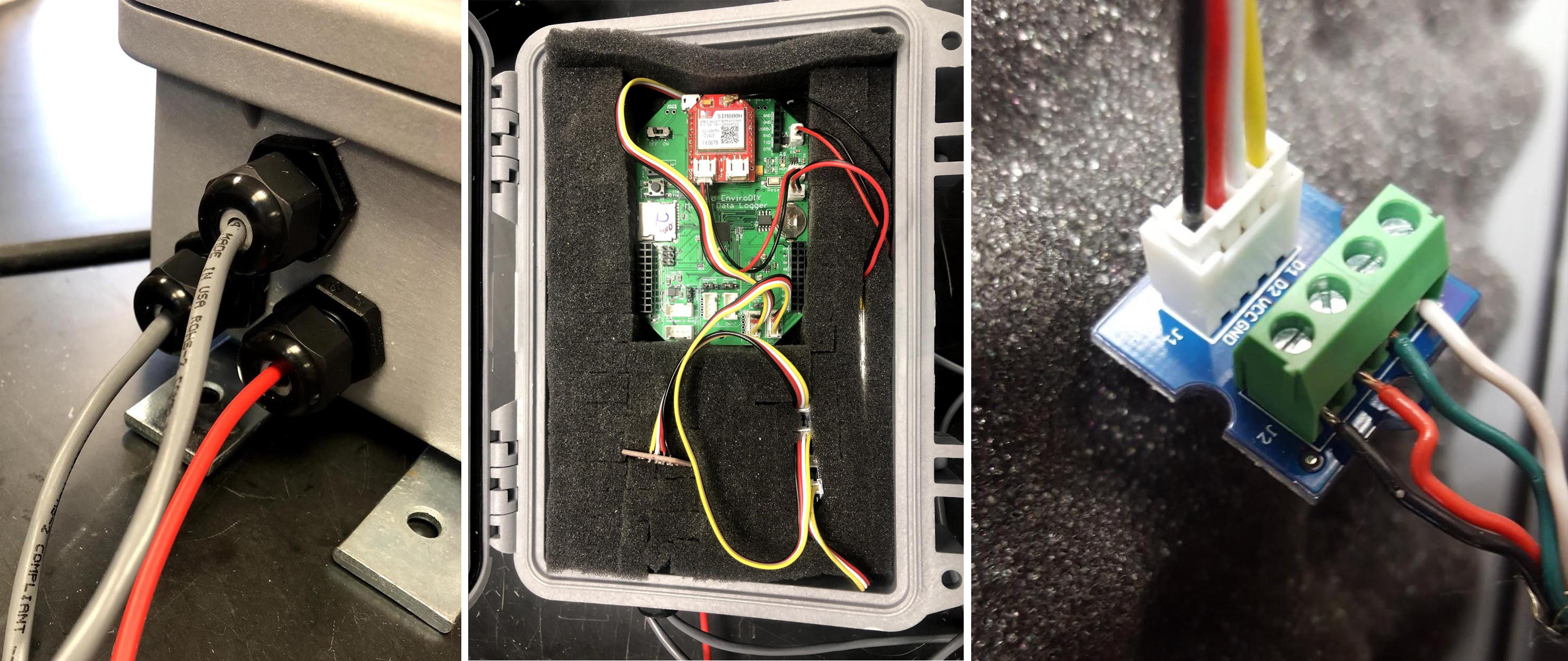

Gosh a great discussion and fantastic to see the detail and how to deploy a rugged Mayfly.

I made a depth sensor some years ago – so appreciate the detail described.

The first time I did it, I solved the sensor problem with a costly arrangement – a raw MSI sensor with an O-ring, and then a custom designed brass housing – it did work well as a rugged sensor for surface water streams. But cost was high for the custom brass housing.

So very impressed with your successes, and the conclusion of the value in sensors, and buy them if available 🙂 (and have the budget).

I have since tried some other sensor configurations, looking for a low cost way of translating physical water depth measurement with a specific accuracy to a traceable number – and its definitely a very specific challenge – water depth to physical units over say an SDI line.

One of the issues with sensors, always there, is the accuracy of the measurement and what is it dependent on, and what other events (like lightening) may cause a problem.

The accuracy – which is really % inaccuracy – is not only how the raw sensors physical readings map to specific units, but how repeatable they are, and for the real world over what temperature range. Ground water is typically a constant temperature and so shouldn’t introduce much variation there. However absolute pressure measurements need an atmospheric compensator measurement, that is then dependent on a wide range of atmospheric measurements. A colleague using a Hobo Onset Absolute pressure device, buried the temperature compensated barometeric measurement device at the foot of the main logging unit to keep the temperature as constant as possible.

For any sensor, you really want to be clear about what accuracy you want in the measurement system, and over what range of measurements. One option I’ve thinking about maybe a variable accuracy.

That is, is the absolute depth from base of the sensor only needs a loose requirement, but the accuracy at the low end of the scale needs to have a greater accuracy for changes over 1week. So I’m looking for a confidence in measuring daily variations, as well as peak measurements (its for a surface water stream)

One thought I’ve had is using a couple of low cost sensors together that measure the physical parameters slightly differently – one could be low cost air pressure sensor with a simple port (MP3V5010) and the other a capacitance wire.

The wire is easier to seal but way problematic to manage a calibrated reading – but indicates changes in water depth independent of temperature. The wire sensor only works over a limited range possible 1m and needs to be vertical

The air pressure sensor with a plastic tube port, and a plastic tube that has a high molecular weight inert silica gel (an idea from a tech support person at a sensor company) to transmit the water pressure and isolate the water from the electronics.

Then the issue becomes sealing the electronics in a water tight container.

What experience has taught me, is figure out how to do layered sealing – a mechanical layer, and then 2 layers of water sealing. If it can be lowenough cost then epoxy all the electronics.

Low water permeability epoxy (EpoxiesEtc) are expensive and there needs to be a simple way of mixing it and using it.

https://www.epoxies.com/_resources/common/userfiles/file/Epoxies_WP_AdhesiveMixingErrors_v8.pdf

So one idea for sealing/epoxying and using very little, is for all the electronics to fit in a 1″ sch 40 tube, then encase the electronics in a 1″ heatshrink. Fold the heatshrink at each end and apply the mixed epoxy in the fold, so using a double seal – the fold (with a small plastic tube running through) and then epoxy each side of the fold. Then activate the heatshrink with a heatgun to shrink it round the electronics. Then fill in the low volume center with epoxy and finally fold at top with wires/plastic pipe transiting the protective fold. So apologies, a bit difficult to describe and lots of small issues to get right.

So I did make one prototype, and had to put it aside when something else came up, and hope to get back to it …. but I share it in case anybody else is thinking about it. It doesn’t look much ….

http://www.envirodiy.org/wp-content/uploads/ProbeScFront.jpg – Water Depth probe using gas sensor

http://www.envirodiy.org/wp-content/uploads/ProbeScTop.jpg – Top of water depth sensor – prototype using TeensyLC – final device would be enclosed

And the processor with RTC, 16bit ADC & accurate ADC Ref, MKL27Z256VL https://www.digikey.com/products/en?keywords=MKL27Z256VL

I based the prototype electronics on a TeensyLC – with a target of using the Cortex MO MKL27X256 and SDI interface.

I can share more details if anybody is interested.

back to the post – thanks for sharing, and all the magic sources of the little stuff to get it deployed. Yeah!!!