@lilcano

Active 7 years agoForum Replies Created

-

AuthorPosts

-

Hello Hicks,

Thanks for the reply, the sensors are buried completely in the soil as for the length i did not really measure that. Please see the attached file for the complete sketch running on the Arduino, and let me know what you think.

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899100101102103104105106107108109110111112113114115116117118119120121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156157158159160161162163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208209210211212213214215216217218219220221222223224225226227228229230231232233234235236237238239240241242243244245246247248249250251252253254255256257258259/*This is the first code for taking data from the 5TM sensor and showing it on the Arduino serial mornitor//The data is collected from the SDI12 sensor and timestamped then stored onto an SD card */#include <SDI12.h>#include <SPI.h>#include <SD.h>#include <Wire.h>#include "RTClib.h"#define ECHO_TO_SERIAL 1 // echo data to serial port#define WAIT_TO_START 0 // Wait for serial input in setup()#define SYNC_INTERVAL 60000 // mills between calls to flush() - to write data to the carduint32_t syncTime = 0; // time of last sync()#define DATAPIN 5 // change to the proper pin for sdi-12 data pin, I prefer D7SDI12 mySDI12(DATAPIN);//Define the number of sensors connectedRTC_PCF8523 RTC; // define the Real Time Clock object//the digitalpins that connect to the LEDS#define redLEDpin 2#define greenLEDpin 3unsigned long previousMillis = 0;const long interval = 60000; //set the interval (in milliseconds). ex: 60000 = 60 seconds// for the data logging shield, we use digital pin 10 for the SD cs lineconst int chipSelect = 10;// the logging fileFile logfile;//Function for handling errors that occurvoid error(char *str){Serial.print("error: ");Serial.println(str);// red LED indicates errordigitalWrite(redLEDpin, HIGH);while(1);}//Function for the working with the real time clock//and time stamping the data collected from the sensorsvoid timestamp(){// fetch the timeDateTime now = RTC.now();// log time//logfile.print(now.unixtime()); // seconds since 1/1/1970logfile.print(", ");logfile.print('"');logfile.print(now.year(), DEC);logfile.print("/");logfile.print(now.month(), DEC);logfile.print("/");logfile.print(now.day(), DEC);logfile.print(" ");logfile.print(now.hour(), DEC);logfile.print(":");logfile.print(now.minute(), DEC);logfile.print(":");logfile.print(now.second(), DEC);logfile.print('"');#if ECHO_TO_SERIAL//Serial.print(now.unixtime()); // seconds since 1/1/1970Serial.print(", ");Serial.print('"');Serial.print(now.year(), DEC);Serial.print("/");Serial.print(now.month(), DEC);Serial.print("/");Serial.print(now.day(), DEC);Serial.print(" ");Serial.print(now.hour(), DEC);Serial.print(":");Serial.print(now.minute(), DEC);Serial.print(":");Serial.print(now.second(), DEC);Serial.print('"');#endif //ECHO_TO_SERIAL}//Function that runs at the start of the program oncevoid setup (){//Debugging ledsSerial.begin(57600);mySDI12.begin();pinMode(greenLEDpin, OUTPUT);pinMode(redLEDpin, OUTPUT);#if WAIT_TO_STARTSerial.println("Type any character to start");while (!Serial.available());#endif //WAIT_TO_START// initialize the SD cardSerial.print("Initializing SD card...");// make sure that the default chip select pin is set to// output, even if you don't use it:pinMode(10, OUTPUT);// see if the card is present and can be initialized:if (!SD.begin(chipSelect)) {error("Card failed, or not present");}Serial.println("card initialized.");// create a new filechar filename[] = "LOGGER00.CSV";for (uint8_t i = 0; i < 100; i++) {filename[6] = i/10 + '0';filename[7] = i%10 + '0';if (! SD.exists(filename)) {// only open a new file if it doesn't existlogfile = SD.open(filename, FILE_WRITE);break; // leave the loop!}}if (! logfile) {error("couldnt create file");}Serial.print("Logging to: ");Serial.println(filename);// connect to RTCWire.begin();if (!RTC.begin()) {logfile.println("RTC failed");#if ECHO_TO_SERIALSerial.println("RTC failed");#endif //ECHO_TO_SERIAL}digitalWrite(greenLEDpin, LOW); //turn off the onboard LED to start withlogfile.println("Sketch for sampling multiple SDI12 sensors");logfile.print(", ,");for(int i=0; i<=2; i++){logfile.print(" Sensor_Num, Ea, VWC(%), Temp(degC) ");logfile.print(",");}logfile.println();#if ECHO_TO_SERIALSerial.println("Sketch for sampling multiple SDI12 sensors");for(int i=0; i<=2; i++){Serial.print(" Sensor_Num, Ea, VWC(%), Temp(degC) ");}#endif//ECHO_TO_SERIALSerial.println();delay(1000);}void loop (){//unsigned long currentMillis = millis();uint32_t currentMillis = millis();if(currentMillis - previousMillis >= interval || previousMillis == 0) {previousMillis = currentMillis;digitalWrite(greenLEDpin, HIGH); //turn on the onboard LED to show that samples are being takenSerial.print("Time: ");Serial.print(currentMillis/1000); //print out the current time, in secondslogfile.print(currentMillis/1000);Serial.print("-----");timestamp();for (char j = '1'; j <= '3'; j++) { //go through channels 1 to 6tmMeasurement(j);}logfile.println();Serial.println();digitalWrite(greenLEDpin, LOW); //turn off the LED to show that samples are done// Now we write data to disk! Don't sync too often - requires 2048 bytes of I/O to SD card// which uses a bunch of power and takes timeif ((millis() - syncTime) < SYNC_INTERVAL) return;syncTime = millis();// blink LED to show we are syncing data to the card & updating FAT!digitalWrite(redLEDpin, HIGH);logfile.flush();digitalWrite(redLEDpin, LOW);}delay(1000);}void tmMeasurement(char c){ //5TM soil moisture sensorString command = "";float Ea = 0.0;float temp = 0.0;float VWC = 0.0;command += c;command += "M!"; // SDI-12 measurement command format [address]['M'][!]mySDI12.sendCommand(command);delay(500); // wait a secmySDI12.flush();command = "";command += c;command += "D0!"; // SDI-12 command to get data [address][D][dataOption][!]mySDI12.sendCommand(command);delay(500);if(mySDI12.available() > 0){int channel = mySDI12.parseInt();Ea = mySDI12.parseFloat();temp = mySDI12.parseFloat();VWC = (4.3e-6*(Ea*Ea*Ea)) - (5.5e-4*(Ea*Ea)) + (2.92e-2 * Ea) - 5.3e-2 ; //the TOPP equation used to calculate VWC//Serial.print("Sensor:");//logfile.print(",");logfile.print(",");logfile.print(channel);logfile.print(",");//Serial.print(": Ea=");logfile.print(Ea); //apparent dielectric permittivitylogfile.print(",");//Serial.print(", VWC=");logfile.print(VWC); //volumetric water contentlogfile.print(",");//Serial.print("%, Temp=");logfile.print(temp); //Tempeerature//logfile.print("degC .... ");#if ECHO_TO_SERIAL//Serial.print("Sensor:");Serial.print(",");Serial.print(channel);Serial.print(",");//Serial.print(": Ea=");Serial.print(Ea); //apparent dielectric permittivitySerial.print(",");//Serial.print(", VWC=");Serial.print(VWC); //volumetric water contentSerial.print(",");//Serial.print("%, Temp=");Serial.print(temp); //TempeeratureSerial.print(".... ");#endif}mySDI12.flush();}Thanks

Hello Sara,

Thanks for the reply, attached is a copy of the actual raw data and the sensor and arduino are actually places in a field(so not a controlled environment). I was expecting the VWC to reduce with time and not the sinusoidal behavior, Equally the Ea will give similar curve because its used to calculate the VWC using the Topps equation. Please can you take a look at the attached raw data and advice?

Attachments:

Hello,

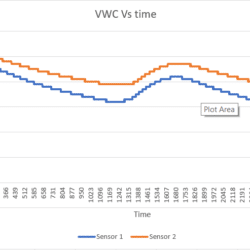

I just checked again and yes i am plotting the VWC. As for the collection of the data i am actually using an SD card shield on the arduino to store the data. As you can see from the image there are two curves each one for the different sensors placed at the same location. After getting this results i decided to take out the SD card shield and run the attach sketch with the arduino connected to my computer and unfortunately i obtain similar results on the arduino IDE serial monitor. please any ideas?

Hello,

Thanks for the quick response.Bellow is the sketch running on the arduino Uno R3. The devices where actually tested on the field(not in a controlled environment).The results shown on the plot is VMC collected every minute from the sensors. Actually the VWC is expected to reduce with time, these results are collected over a period of 3 days. Surprisingly they show a sinusoidal curve and the sensors are places in a sandy loam soil. I am thinking maybe the sketch has some problem. Please do you have any ideas why such results?1234567891011121314151617181920212223242526272829303132333435363738394041424344454647484950515253545556575859606162636465666768697071727374757677787980//This is the first code for taking data from the 5TM sensor and showing it on the Arduino serial mornitor#include <SDI12.h>#define DATAPIN 7 // change to the proper pin for sdi-12 data pin, I prefer D7SDI12 mySDI12(DATAPIN);unsigned long previousMillis = 0;const long interval = 60000; //set the interval (in milliseconds). ex: 60000 = 60 secondsvoid setup (){pinMode(13, OUTPUT);digitalWrite(13, LOW); //turn off the onboard LED to start withSerial.begin(57600);mySDI12.begin();Serial.println("Sketch for sampling multiple SDI12 sensors");delay(1000);}void loop (){unsigned long currentMillis = millis();if(currentMillis - previousMillis >= interval || previousMillis == 0) {previousMillis = currentMillis;digitalWrite(13, HIGH); //turn on the onboard LED to show that samples are being takenSerial.print("Time: ");Serial.print(currentMillis/1000); //print out the current time, in secondsSerial.print(" ---- ");for (char j = '1'; j <= '2'; j++) { //go through channels 1 to 6tmMeasurement(j);}Serial.println();digitalWrite(13, LOW); //turn off the LED to show that samples are done}delay(1000);}void tmMeasurement(char c){ //5TM soil moisture sensorString command = "";float Ea = 0.0;float temp = 0.0;float VWC = 0.0;command += c;command += "M!"; // SDI-12 measurement command format [address]['M'][!]mySDI12.sendCommand(command);delay(500); // wait a secmySDI12.flush();command = "";command += c;command += "D0!"; // SDI-12 command to get data [address][D][dataOption][!]mySDI12.sendCommand(command);delay(500);if(mySDI12.available() > 0){int channel = mySDI12.parseInt();Ea = mySDI12.parseFloat();temp = mySDI12.parseFloat();VWC = (4.3e-6*(Ea*Ea*Ea)) - (5.5e-4*(Ea*Ea)) + (2.92e-2 * Ea) - 5.3e-2 ; //the TOPP equation used to calculate VWCSerial.print("Sensor:");Serial.print(channel);Serial.print(": Ea=");Serial.print(Ea); //apparent dielectric permittivitySerial.print(", VWC=");Serial.print(VWC); //volumetric water contentSerial.print("%, Temp=");Serial.print(temp); //TempeeratureSerial.print("degC .... ");}mySDI12.flush();}Attachments:

So i have decided to improve my project by adding a data logger shield from adafruit. can seam to get the data from the attached decagon 5TM sensors. Please can any one help with what i am doing wrong in my sketch.

#include <SPI.h>

#include <SD.h>

#include <Wire.h>

#include “RTClib.h”

#include <SDI12.h>// A simple data logger for the Arduino digital pins

// how many milliseconds between grabbing data and logging it. 1000 ms is once a second

#define LOG_INTERVAL 60000 // mills between entries (reduce to take more/faster data)// how many milliseconds before writing the logged data permanently to disk

// set it to the LOG_INTERVAL to write each time (safest)

// set it to 10*LOG_INTERVAL to write all data every 10 datareads, you could lose up to

// the last 10 reads if power is lost but it uses less power and is much faster!

#define SYNC_INTERVAL 60000 // mills between calls to flush() – to write data to the card

uint32_t syncTime = 0; // time of last sync()#define ECHO_TO_SERIAL 1 // echo data to serial port

#define WAIT_TO_START 0 // Wait for serial input in setup()// the digital pins that connect to the LEDs

#define redLEDpin 2

#define greenLEDpin 3#define DATAPIN 7 // change to the proper pin for sdi-12 data pin, I prefer D7

SDI12 mySDI12(DATAPIN);// The analog pins that connect to the sensors

//#define photocellPin 0 // analog 0

//#define tempPin 1 // analog 1

//#define BANDGAPREF 14 // special indicator that we want to measure the bandgap//#define aref_voltage 3.3 // we tie 3.3V to ARef and measure it with a multimeter!

//#define bandgap_voltage 1.1 // this is not super guaranteed but its not -too- offRTC_PCF8523 RTC; // define the Real Time Clock object

// for the data logging shield, we use digital pin 10 for the SD cs line

const int chipSelect = 10;// the logging file

File logfile;

void tmMeasurement(char c);void error(char *str)

{

Serial.print(“error: “);

Serial.println(str);// red LED indicates error

digitalWrite(redLEDpin, HIGH);while(1);

}void setup(void)

{

Serial.begin(9600);

Serial.println();// use debugging LEDs

pinMode(redLEDpin, OUTPUT);

pinMode(greenLEDpin, OUTPUT);#if WAIT_TO_START

Serial.println(“Type any character to start”);

while (!Serial.available());

#endif //WAIT_TO_START// initialize the SD card

Serial.print(“Initializing SD card…”);

// make sure that the default chip select pin is set to

// output, even if you don’t use it:

pinMode(10, OUTPUT);// see if the card is present and can be initialized:

if (!SD.begin(chipSelect)) {

error(“Card failed, or not present”);

}

Serial.println(“card initialized.”);// create a new file

char filename[] = “LOGGER00.CSV”;

for (uint8_t i = 0; i < 100; i++) {

filename[6] = i/10 + ‘0’;

filename[7] = i%10 + ‘0’;

if (! SD.exists(filename)) {

// only open a new file if it doesn’t exist

logfile = SD.open(filename, FILE_WRITE);

break; // leave the loop!

}

}if (! logfile) {

error(“couldnt create file”);

}Serial.print(“Logging to: “);

Serial.println(filename);// connect to RTC

Wire.begin();

if (!RTC.begin()) {

logfile.println(“RTC failed”);

#if ECHO_TO_SERIAL

Serial.println(“RTC failed”);

#endif //ECHO_TO_SERIAL

}logfile.println(“millis,stamp,datetime,sensor,ea,vwc,temp “);

#if ECHO_TO_SERIAL

Serial.println(“Sketch for sampling multiple SDI12 sensors”);

Serial.println(“millis,stamp,datetime,sensor,ea,temp”);#endif //ECHO_TO_SERIAL

Serial.println();

// If you want to set the aref to something other than 5v

//analogReference(EXTERNAL);

delay(1000);

}void loop(void)

{//Now lets look at the timestamp

DateTime now;// delay for the amount of time we want between readings

delay((LOG_INTERVAL -1) – (millis() % LOG_INTERVAL));digitalWrite(greenLEDpin, HIGH);

// log milliseconds since starting

uint32_t m = millis();

logfile.print(m); // milliseconds since start

logfile.print(“, “);

#if ECHO_TO_SERIAL

Serial.print(m); // milliseconds since start

Serial.print(“, “);

#endif// fetch the time

now = RTC.now();

// log time

logfile.print(now.unixtime()); // seconds since 1/1/1970

logfile.print(“, “);

logfile.print(‘”‘);

logfile.print(now.year(), DEC);

logfile.print(“/”);

logfile.print(now.month(), DEC);

logfile.print(“/”);

logfile.print(now.day(), DEC);

logfile.print(” “);

logfile.print(now.hour(), DEC);

logfile.print(“:”);

logfile.print(now.minute(), DEC);

logfile.print(“:”);

logfile.print(now.second(), DEC);

logfile.print(‘”‘);

#if ECHO_TO_SERIAL

Serial.print(now.unixtime()); // seconds since 1/1/1970

Serial.print(“, “);

Serial.print(‘”‘);

Serial.print(now.year(), DEC);

Serial.print(“/”);

Serial.print(now.month(), DEC);

Serial.print(“/”);

Serial.print(now.day(), DEC);

Serial.print(” “);

Serial.print(now.hour(), DEC);

Serial.print(“:”);

Serial.print(now.minute(), DEC);

Serial.print(“:”);

Serial.print(now.second(), DEC);

Serial.print(‘”‘);

#endif //ECHO_TO_SERIAL

//for(char j=’1′;j<=’3’;j++){

tmMeasurement(j);

//}

Serial.println();

}

//delay(1000);

// Now lets look at collecting the data from the sensorsvoid tmMeasurement(char c){

String command = “”;

float Ea = 0.0;

float temp = 0.0;

float VWC = 0.0;

command += c;

command += “M!”; // SDI-12 measurement command format [address][‘M’][!]

mySDI12.sendCommand(command);

delay(500); // wait a sec

mySDI12.flush();command = “”;

command += c;

command += “D0!”; // SDI-12 command to get data [address][D][dataOption][!]

mySDI12.sendCommand(command);

delay(500);if(mySDI12.available() > 0){

int channel = mySDI12.parseInt();

Ea = mySDI12.parseFloat();

temp = mySDI12.parseFloat();VWC = (4.3e-6*(Ea*Ea*Ea)) – (5.5e-4*(Ea*Ea)) + (2.92e-2 * Ea) – 5.3e-2 ; //the TOPP equation used to calculate VWC

logfile.print(“, “);

logfile.print(channel);

logfile.print(“, “);

logfile.print(Ea);

logfile.print(“, “);

logfile.print(VWC);

logfile.print(“, “);

logfile.print(temp);#if ECHO_TO_SERIAL

Serial.print(“, “);

Serial.print(channel);

Serial.print(“, “);

Serial.print(Ea);

Serial.print(“, “);

Serial.print(VWC);

Serial.print(“, “);

Serial.print(temp);#endif //ECHO_TO_SERIAL

/*/analogRead(photocellPin);

//delay(10);

//int photocellReading = analogRead(photocellPin);//analogRead(tempPin);

//delay(10);

int tempReading = analogRead(tempPin);// converting that reading to voltage, for 3.3v arduino use 3.3, for 5.0, use 5.0

float voltage = tempReading * aref_voltage / 1024;

float temperatureC = (voltage – 0.5) * 100 ;

float temperatureF = (temperatureC * 9 / 5) + 32;logfile.print(“, “);

logfile.print(photocellReading);

logfile.print(“, “);

logfile.print(temperatureF);

#if ECHO_TO_SERIAL

Serial.print(“, “);

Serial.print(photocellReading);

Serial.print(“, “);

Serial.print(temperatureF);

#endif //ECHO_TO_SERIAL

*//*

// Log the estimated ‘VCC’ voltage by measuring the internal 1.1v ref

analogRead(BANDGAPREF);

delay(10);

int refReading = analogRead(BANDGAPREF);

float supplyvoltage = (bandgap_voltage * 1024) / refReading;logfile.print(“, “);

logfile.print(supplyvoltage);

#if ECHO_TO_SERIAL

Serial.print(“, “);

Serial.print(supplyvoltage);

#endif // ECHO_TO_SERIALlogfile.println();

#if ECHO_TO_SERIAL

Serial.println();

#endif // ECHO_TO_SERIAL

*/

digitalWrite(greenLEDpin, LOW);// Now we write data to disk! Don’t sync too often – requires 2048 bytes of I/O to SD card

// which uses a bunch of power and takes time

if ((millis() – syncTime) < SYNC_INTERVAL) return;

syncTime = millis();// blink LED to show we are syncing data to the card & updating FAT!

digitalWrite(redLEDpin, HIGH);

digitalWrite(redLEDpin, LOW);

}

logfile.flush();}

i tied changing the baud rate as you suggested, but unfortunately i see the characters when i print use the arduino software serial monitor. when i use the X-ctu console i don’t have the characters.

Wondering do you have any specific arduino boards you will recommend for use in outdoor experiments?

Thanks

What I mean by “its not working” is, I still have some extra characters on the Arduino serial monitor when the message “goodnight moon” is printed.

I am using an FTDI cable 5V VCC-3.3V I/O to program the Arduino Fio.

During the programming I make sure the Xbee is not on the Fio board.

For the configuration of the Xbee modules I used the XCTU software changing the baud rate of both xbees to 57600.

The second xbee is connected to the PC with the help of xbee explorer from sparkfun and its set to coordinator mode.What I really want to try is print a message from the Arduino to the Arduino serial monitor without any extra characters using the Xbee modules installed.

Thanks

Bellow is a sample sketch I am trying to run to make sure I get the software serial going but still it doesn’t work.

#include <SoftwareSerial.h>

SoftwareSerial mySerial(10, 11); // RX, TX

void setup() {

// Open serial communications and wait for port to open:

Serial.begin(57600);

while (!Serial) {

; // wait for serial port to connect. Needed for native USB port only

}Serial.println(“Goodnight moon!”);

// set the data rate for the SoftwareSerial port

mySerial.begin(4800);

mySerial.println(“Hello, world?”);

}void loop() { // run over and over

if (mySerial.available()) {

Serial.write(mySerial.read());

}

if (Serial.available()) {

mySerial.write(Serial.read());

}

}I am transmitting the data to another xbee connected to my computer with the help of the xbee explorer and its setup as coordinator. I tried using the softwareSerial library and connecting the Tx and Rx ports to pins 10 and 11, but the results did not get better. Please let me know if you have any other idea.

I am using the Arduino Fio, because it has Xbee slots already available on the board. As of the board rate when programming the Xbee I set them to 57600. So I think that’s not the problem. I am trying to see how many hardware serial ports Fio has. I will think they should have more than 1 port for the transmission since they already support xbee modules on the board. Do you think I meight have an issue with the programming of the xbee?

Thanks

-

AuthorPosts

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of