Forum Replies Created

-

AuthorPosts

-

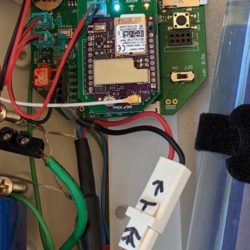

@mbarney on Mayfly 1.1 I connect SJ17 – that enables the Blue Network Status LED, and indicates the progress of the LTE-CATME connection. Off – no connection, ( I think) ON – attempting connection, FLASHING – connecting

For Mayfly1.1 I also

Solder SJ15 – assumes 4400mA hr battery, and allows 1A charge, but that depends on solar panel.

J27 desolder A6-Vin , solder A6-LiPo ~ more accurate Vbat reading.

I’ve released an expanded Modbus/RS485 Wingboard for community design review

https://github.com/EnviroDIY/Mayfly-Modbus-Wing/tree/master/knh002-MayflyWingShield/rev8

I’d welcome design comments, on https://github.com/EnviroDIY/Mayfly-Modbus-Wing/issues/3 by Monday 2022-July-20 12noon PST. Easier to correct any possible problems early on, than find them later on the PCB. As the old clothes tailor saying goes “measure three times, cut once”.

Discussion on desired Modbus usage or general questions could be made here. I should note that this is a private initiative, not funded by EnviroDIY, but I am using it as a part of a public discussion for an open source board design.

2022-06-01 at 12:24 PM in reply to: Adding a new modbus sensor using current ones as inspiration. #17064Hello Erik, hmm perhaps I’m coming from too many years of reading code,

Yes the order matters for the code, that the instance follows the the constructor.

What you are looking at I think is “// .. sensor” , and that is a comment

It does look like it may have been swopped, but its only descriptive text. Getting descriptions to match the code takes time and refinement. The “code warrior” answer; is read the code

.

FYI IMHO adding a new protocol for a Modbus device is jumping into some “deep water”. Good luck!

2022-05-31 at 12:07 PM in reply to: Adding a new modbus sensor using current ones as inspiration. #17058Hello Erik, I’m sorry I still don’t understand your question.

2022-05-30 at 2:11 PM in reply to: Adding a new modbus sensor using current ones as inspiration. #17054Hello Erik, sounds like you are on the path to learning Cpp. One issue to keep in mind is that the code is what happens, the reality check, the documentation is for readability. You may want to list what gas sensor you are looking at for the max help.

So I don’t follow your question – where do you get the code snippet from the first section which says there are two power pins “nlAdapterPower” and nanolevelPower which looks reasonable.

Then in the constructor KellerNanolevel.h they map to int8_t and int8_t – the name is only descriptive, it isn’t used for anything.

Part of new code is having a plan including figuring out what you need to learn. a) can you get enough technical detail for the plan to be likely to work – ie for your case the Modbus map of the gas sensor b) The other part of coding is set up a target test bench. b1) The first part of a test bench is proving that the test bench is working, b2) typically by enabling debug and checking the message flow on a known working sensor and then b3) making modifications for your new target sensor. Do you have ANY ModularSensors modbus sensors that you could start with? Just a thought

For powering I am using the new Solar2 connector.

It requires a very precise diameter solid core wire – and took me some time to find it as old fashioned “Bell Wire” 20AWG, which I got from local Lowes store.

The needs to be – 20-26 AWG solid core. It also needs exactly matched wire strippers. If the wire strippers are too small a dia, its likely to nick the solid core wire, making it more prone to failure.

The connector is

“Phoenix 1778832″,”TERM BLOCK PLUG 2POS STR 2.5MM” and requires

or digikey https://www.digikey.com/en/products/detail/phoenix-contact/1778832/2625556

Another nifty new feature I found with Mayfly1.x is soldering the SJ17 LED10 Blue “- which at least for Digi modules is “network connection”. It activates when the module comes out of sleep, then when the device is connecting to the network it flashes. And finally when it disconnects from the network it turns off. A good help in checking operations, and slight waste of power for normal operation. Normally I like to have a LED activate when there is maintenance activity – (say for 10minutes after reset, or on a maintenance wake button press operation) but that has to be designed in at system level, either sw or hw and not figured that out yet.

An update on measuring battery voltage. I’ve purchased a number of Mayfly1.1 for a project. And on testing one of this batch, the noise level of measuring LiPo is better – which is great. The noise level of resistors is part of their specification, or it might be just luck in this case. Often a batch of noisy resistors is because the manufacture has selected out the low noise resistors.

The testing is at my office desk – which as I am finding out, is also electrically a noisy environment.

For release testing I’ve moved it to an outside environment and the noise level is even better, which is soooo nice.

Here is the graph of the lower noise measurement, where there is a cutoff of transmitting data at LiPo=3.8V (measured from A6 Blue line) with a more accurate 12bit measurement (black line).

This is 4 days of testing, with accelerated 2min readings and if the LiPo V was above 3.8V immediately transmitted to MMW. When it dropped below 3.8V it queued the readings. Then when the solar came back, charged the battery and the readings went up 3.8V, it transmitted the data. The black line is the more accurate 12bit reading, which in this specific Mayfly the blue line A6 is fairly accurate.

Graph with Mayfly A6 and more accurate 12bit

Attachments:

Hi Jake, my take is its complex to be able to decode why MMW isn’t showing data ~ it needs a system look, location aspects (solar looks excellent) , maintenance inspection of site, reliability of hardware/battery/mechanics reliability of software on the Mayfly, reliability of software at MMW

It would be useful to know your configuration including battery capacity and make, software version upgrades, and site sensor/maintenance as well as a picture of the insides and any observations/pictures of condensation on the board or growths. As Shannon indicated for your particular station, it would be useful to compare it against the readings taken on the uSD, and look at the RSSI.

Clearly though, for all the visible parameters of good solar aspect, apparently working Mayfly – it would be nice if the data could just be available …. for maybe 5years … or how long?. A dream.

What does it take to achieve that, is pretty challenging.

However taking a download of data, see PMTU37-1_TimeSeriesResults_220517_1145.xlsx ~ and constructing a reliability story – – the system started pre-pandemic (had to throw that in) 2019 Nov 10th .. fast forwarding to 2022 Mar-1 and looking at the data – and time difference between samples, it looks to be just an occasional data loss. Then Apr 10 to Apr 20th there is a 10day loss, followed by losses that are in the range 4-13hours. Could this be what has been seen with https://github.com/ODM2/ODM2DataSharingPortal/issues/605

For your system, the dribbling losses, is that the main software does not support reliable delivery. That is the software takes a reading, attempts to deliver it to MMW and doesn’t verify its been delivered. Wireless for a specific location needs characterizing, think of the times when a cell phone doesn’t work, and then you need to shift around to find a place. As it appears cyclical, it could be that the wind changes in the afternoon, and reduces the signal strength. This might show if you could see the RSSI through the times its not reporting. Your station level of -77dBm appears to be good. The measurement is actually the measured signal strength from the last attempt, and your station numbers look reasonable once it starts up, though there are a few at -100dBm which is much worse than -77dBm

However the post 2022 Apr-28th many hours of losses are much more difficult to figure out – perhaps you could get a site visit swop out the uSD, inspect the board for visible signs of failure, and then share the uSD contents.

I do have reliable delivery working in my branch, and I have said I would submit to the main software git repository – a so called PullRequest (PR) but haven’t had the cycles to do it yet. https://github.com/neilh10/ModularSensors/releases . It also takes resources from Stroud to be able to accept it and do quality assurance testing – which is a challenging area.

There are two systems I put together that use the Mayfly 0.5b, Digi LTE on Carrier and 44000mAh, and appear very successful, except for what appears some intermittent failures on the MMW side in mid Apr, ending Apr 28th

https://monitormywatershed.org/sites/TUCA_PO03/ – it does have good signal strength of RSSI -57dbm

These data losses at MMW sorta look like your losses, so it could be intermittent MMW as whatever is causing https://github.com/ODM2/ODM2DataSharingPortal/issues/605 hasn’t been commented on.

On my system TUCA-Na13 since Apr 29th I saw one data loss on May 15, which I wouldn’t expect as it has reliable delivery and could be MMW. TUCA_PO03 has no losses since Apr 29th. Another system local to me https://monitormywatershed.org/sites/nh_LCC45/ that is over WiFi hasn’t had any data losses since Apr 29th

I am focused on a delivery of devices to a TU California project on the Russian River, and once complete in the next month hope to do the PR to the main software https://github.com/EnviroDIY/ModularSensors/issues/194 – which won’t necessarily help you, but may help future builds for more software reliability.

@James_NZ – I’m curious, just wondering how many RS485’s stations are you looking at and your planning project timeline.

What sort of instruments/powering are you looking to connect to.

There is a forward looking discussion on issues here, though the timeline for anything being built, I’m guessing is really dependent on specific project drivers. https://github.com/EnviroDIY/Mayfly-Modbus-Wing/issues/3

For the solar connecter, I colour the socket and the jack in an acrylic orange so that there is a visual match. The LiIon battery in a cooler blue. Of course have to be careful to only get the acrylic paint on the outside of the jack and not have leak inside. Its not perfect, but provides a little clue.

Attachments:

-

AuthorPosts

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of