Forum Replies Created

-

AuthorPosts

-

The old Campbell OBS3 turbidity sensor was an analog-output sensor that had 2 separate voltage outputs, one 5v power supply wire, and 3 ground wires, which is why I designed the old version of the 6-pin screw terminal board that way, because we primarily used it with the OBS3 sensors and connected it to one of the Aux Analog Grove jacks on the Mayfly board.

The Campbell ClariVUE10 sensor is a digital-output sensor that uses SDI-12 protocol and only has one signal output and 2 ground wires (plus the one 12v power wire). And because we wanted a new screw terminal board that gave people the option of also combining signal pins (for hooking two SDI-12 sensors to one board) or adding resistor dividers for analog sensors, I designed the new multi-purpose screw terminal board to replace the old version and give users the option of configuring the board for different types of sensors.

In your case, you are able to use the old style screw terminal board with your Mayfly v1.1 board and a ClariVUE 10 sensor if you connect the wires as follows:

- Black wire (ground) and clear wire (shield) to any of the screw terminal board’s GND pins

- Red wire (12v power) to the screw terminal board’s VCC pin

- White wire (SDI-12 data) to the screw terminal board’s D2 pin

Then you’ll need to connect the Grove cable from the screw terminal board to either of the two Grove sockets in the center of the Mayfly (the one’s labeled D4-7 SDI-12). You’ll also want to make sure you move the little jumper block next to that one socket from the default 3v position to the 12v position. Once that is connected and the switched power (D22) is set high so that the sensor is powered, you can communicate with it through the D7 pin. The sensor ships from the factory with the default SDI-12 address of “0”, so you might want to change it to something else if you don’t want it to conflict with any other SDI-12 sensors you connect to the Mayfly at the same time. If you want to use a Hydros21 CTD sensor along with the ClariVUE10, connect the Hydros21 to the Mayfly’s other SDI-12 Grove jack and keep that one at the default 3v jumper position (we’ve found that the Hydros21 sensors work best at 3v), but you’ll have to change the Hydros21 channel number to something other than its default “0” channel, otherwise it doesn’t respond properly to measurement commands. We typically use “1” for the CTD channel and “2” for the turbidity channel. We haven’t published an example sketch of using a ClariVUE10 sensor yet because we’re finalizing our testing of various configurations with the new sensors, but I’m hoping to publish that example next week on Github.

Readers should note that the Mayfly v1.1 boards are the only ones capable of powering a ClariVUE10 turbidity sensor directly from the Mayfly board. Older Mayfly boards (v1.0 and earlier) will need a separate 12v boost adapter (coming soon) or a separate 12v power source to power the sensor directly since the older Mayfly board don’t have the ability to generate the proper power for the ClariVUE sensors.

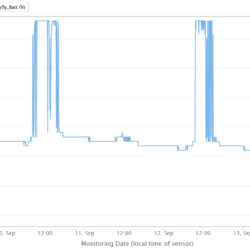

As Neil mentioned above, the yellow LED that is labeled SOLAR only indicates when a charge current is being applied to a battery, so if a battery if fully charged (~4.2v), the LED will not be on. The charging circuity of the Mayfly v1.1 boards is configured so that the solar panel provides voltage directly to the Mayfly’s main power regulators when the sun is out (and also charges the battery) and it uses the Lipo battery as kind of a “backup” source in case the Mayfly draws more current than the panel can provide. When there’s insufficient power collected by the solar panel (like at night or in really shady locations) then the main power for the Mayfly comes from the battery. If you’re using analog pin A6 to monitor the input voltage, you’ll see the raw battery voltage at night (anywhere from 3.5v to 4.2v), and during the day you’ll usually see something between 4.1v and 4.25v (depending on the amount of sunlight). In the attached graph image below, you can see the raw battery voltage is around 3.85v.

You can actually get useful information from this plot like that because it shows you what days were sunny and what days were cloudy, which could help you understand why the underlying raw battery voltage might increase or decrease over time. For example, in the plot below you can see it was completely sunny on September 9, mostly sunny on Sept 10, totally cloudy on Sept 11 (no charging at all), and mostly sunny on the 12th and 13th. Every station is going to have a different charging pattern based on tree canopy, time of year, weather, obstacles, etc, but having the graph showing the input voltage to the Mayfly can be very useful for monitoring the overall status of a station. Also, if a Mayfly is being powered directly through its USB port (with or without a Lipo also connected to the Lipo socket), then the voltage measured by the analog A6 input will show 4.95v.

If you would rather monitor the raw Lipo battery voltage and not see the swings of the solar panel (or USB) input, then you can follow the directions mentioned below, which come from the Mayfly Jumper Settings page.

SJ27: Analog pin A6 connected to either combination Voltage in (default) or direct Lipo battery socket. The default setting works best so that the Mayfly can sense the input voltage of whichever source is highest. With just a Lipo connected, A6 will see the battery voltage (~3.7v). If a solar panel is connected, then A6 will see approximately 4.2v during full sun. If a USB cable is connected, A6 will see 4.9v. If you want to see only the raw Lipo battery voltage independent of the higher voltage from the solar panel, change the solder jumper to Lipo.

Attachments:

The components on the Mayfly circuit board are rated to withstand the industrial temperature range of -40C to +85C. Here in Pennsylvania, our loggers don’t normally see that full range during normal deployments, but this summer we frequently reached almost 60C with one of our loggers that is mounted in an open field inside a clear plastic Pelican case. Our other nearby stations in the standard opaque tan Pelican cases reach around 40C most summer days. In previous winters they measured down to -25C with no problems. Likewise, the lipo battery packs have done well in all the stations except ones that have condensation in them, because we’ve found that the blue 4400mAh battery packs are susceptible to damage from being exposed to moist environments because the metal tabs under the plastic end caps will rust very easily and cause the battery to open-circuit. In stations that stay dry inside, usually with the help of desiccant packs, can use the same battery for multiple years with no problems. We’ve got several stations that are still using the same Mayfly and lipo pack from 5 years ago and have been in continuous operation with no issues.

Mayfly v1.x power usage (with no external sensors attached) and both LED dipswitches off (the brown/white slide switches between the main power switch and the vertical SD card socket) is as follows:

Mayfly current when board is powered and idle: 6.5 mA

Mayfly current when MCU put to sleep and no microSD card in socket: 0.27 mA (or 270 uA)

Mayfly current when asleep with microSD card in the socket: 0.43 mA (or 430 uA)End device certification for an open source DIY project like this is nearly impossible, since there’s an infinite number of combinations that users can configure their station with various equipment, accessories, antennas, not to mention all the ways they can change the actual code running on the main processor board. That’s why we try to use modular telemetry devices that are certified by most carriers, however Verizon has always been picky about allowing DIY devices on their networks. I’m unfamiliar with REVX, but I know other people have had success using other non-certified (and non-EnviroDIY) devices with Verizon networks with other sim card providers.

We’ve release several different Mayfly Data Logger hardware versions in the past few years, so I’d need to know which version you’re using. I’m assuming a v1.0 or 1.1 since you mentioned deactivating the LEDs using the dip switches. But it also depends on the sampling interval you’re planning to use (time between measurements when the Mayfly is sleeping), active sample duration (time it takes to make a sensor reading) and the total time the Mayfly will be awake during the sampling and recording/transmitting period, what sensors you’ll be using, will you have a microSD card on board that you’ll write to every sample, will there be a telemetry module (wifi, cellular, radio, etc), and what’s the temperature range the station will be subjected to during the deployment.

The data file on your Mayfly’s memory card contains the UUID information for the original station, so even though you’ve moved the station to a new physical location and created a brand new site on MMW for the new location, the data file still contains the UUID codes that correspond to the original MMW site, and the database is smart enough to prevent people from manually uploading data from the wrong stations. You’ll need to reprogram your Mayfly board using the Arduino IDE, and paste the UUID codes from your newly-created MMW site into the appropriate section of the Arduino code. Once you do that, you’ll be able to manually upload the data correctly.

No, the old LTEbee Adapter should not be used with a Mayfly v1.x board. You simply plug the Digi board directly into the Mayfly v1.x board with no adapter at all. Make the changes to the jumpers I mentioned above and you’ll enable the white and blue status LEDs that are built into the new Mayfly boards. The only thing missing is the orange RSSI light, but it didn’t always work right, plus that parameter is reported digitally and is captured by your sketch and will be transmitted to MMW anyway.

The purpose of the now-discontinued “EnviroDIY LTEbee Adapter” was to allow people to use the Digi brand LTE cellular module with the Mayfly v0.5 boards by doing 3 main thing: providing sufficient power (current) to the cell module, connecting pin 13 of the Digi board to pin 12 of the Mayfly bee socket, and giving the user some LEDs to show status of the module (because the Digi boards have no lights themselves). When I designed the Mayfly 1.0 boards last year, I included all those features into the Mayfly’s new design, so people can now use a Digi board without the need for the bulky EnviroDIY adapter board in between.

The Mayfly v1.0 and v1.1 boards have sufficient power on the bee socket now (1 Amp dedicated solely to the bee socket) so they no longer need that little jumper wire to connect between the Lipo socket and the cell module like on previous versions. On Mayfly v1.0 and v1.1, the default setting is for the bee socket to be powered only when pin 18 is high. This action is dictated by SJ18, so leave it as it is (set to D18) and make sure your Arduino sketch code has modemVccpin set to 18.

Then, to change the bee status pin from the usual Bee pin 12 to Bee pin 13, move the solder blob on SJ19 from 12 to 13. This status pin is monitored by Mayfly pin D19, so in your code, make sure modemStatusPin is set to 19.

Then if you want to see when the modem is turned on (white LED) and it network status (blue LED – it’ll blink or be solid based on whether it is actively connected or not) put a small blob of solder on jumpers SJ16 and SJ17.

That’s all the changes you need to make to the v1.0 or v1.1 board in order to use a Digi cell board with the Mayfly. If you ever decide to use an EnviroDIY LTE cell board (with the SIM7080 module on it), you’ll need to put solder jumper SJ19 back in its original position. It’s fine to leave the Mayfly’s LEDs jumpered with the SIM7080 cell boards, but it’s kind of unnecessary since there are 2 LEDs already included on the cell board, making them redundant.

If you’re using the ModularSensors example sketch that’s currently on Github called DRWI_DigiLTE, note that it’s written for the v0.5 boards, so you’ll need to make the changes mentioned above for the modemVccPin (set it to 18 instead of -2) and then you also need to change the modemResetPin from 20 to A5. Previous versions of the Mayfly had the modem reset pin wired to Mayfly D20, but all new versions of the Mayfly have the modem reset connected to A5.

That should be everything you need to do in order to get the Digi cell boards to operate on the Mayfly v1.0 or v1.1 boards. Give that a try and let us know if it’s successful.

Onewire sensors like the DS18b20 don’t like to have their bus power cycled on and off. Back when I last experimented with them (with a different sketch not related to ModularSensors), if you’ve got the sensor connected to the switched power supply, you had to do “DSsensors.begin();” each time the logger woke and powered up the switched power bus. Only then will the DS18b20 be seen by the Mayfly. So I just put that command in the loop right after the Mayfly wakes up from sleep.

The easy solution to this is to just connect the DS18b20 to the Mayfly’s D5-6 Grove jack and put the power-select jumper to “3.3v const”(it’s default position) that way the Onewire sensor is constantly powered and won’t “disappear” after the pin 22 switched power is cycled. Having a constantly powered Grove jack for I2C and Onewire peripherals is exactly why I designed the Mayfly’s D5-6 jack power selection options.

-

AuthorPosts

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of

Welcome to EnviroDIY, a community for do-it-yourself environmental science and monitoring. EnviroDIY is part of